VJ Instruments'

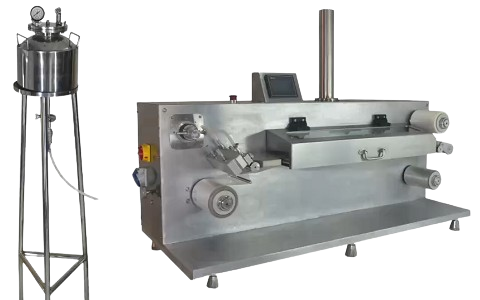

Advanced TDP & ODF Machine Pilot Scale

The VJ Instruments Advanced TDP & ODF Machine Pilot Scale Machine is an advanced solution for developing transdermal therapeutic delivery system laminates and edible films. With precise coating and lamination capabilities, it ensures high product quality and accuracy. The machine’s user-friendly design, temperature control, and observation features make it efficient for small-scale production. Operating with a balcony configuration, it coats a 150 mm wide web continuously, maintaining a thickness variation of ±1%. The drying process is facilitated by an electrically heated stainless steel plate, and evaporated solvents are efficiently removed by ventilators. The final product is a meticulously coated and laminated film, rewound for further use. The VJ Instruments machine stands out for its innovation, precision, and streamlined operation.

Introducing the VJ Instruments Film Former Coating Machine for TDP & ODF Production

Application

The VJ Instruments tabletop Film Former coating machine is versatile, serving two primary purposes:

TDS-Patches: It facilitates the development and production of Transdermal Therapeutic Delivery System (TDS) laminates, ensuring precise coating and lamination for pharmaceutical applications.

EDF/ODF: This machine also enables the creation of Edible Films/Oral Dissolvable Films (EDF/ODF) without the need for further modification.

The machine’s key features include:

- Coating Head with an ultra-precise coating knife, ensuring exceptional product quality with an accuracy of ±1% across the entire coating width.

- Balcony-style construction, with electrical and driving components mounted on a 1400 x 540 mm plate.

- Front-mounted components, including the coating head, winder shafts, web guiding elements, and dryer cabin.

- Adjustable temperature settings, pump delivery rates, and web speed controls, all conveniently located on the top of the machine for ease of operation.

Operation

The operation of the VJ Instruments Film Former coating machine is straightforward:

- The substrate is mounted on a 3″ diameter unwinder shaft on the left side of the machine.

- The web is pulled through the machine by the rewinder on the right side.

- As the web passes through the machine, it is guided around a coating roll equipped with the precision coating knife, which evenly spreads the desired fluid onto the passing web.

- The web then enters the dryer cabin, where it passes over a heated stainless steel plate, gradually reaching a temperature of up to 90°C. Solvents evaporate during this process and are vented away.

- Lamination with a protective covering foil can be applied immediately after drying, enhancing the final product’s durability and functionality.

- The finished laminate is rewound on the rewinding shaft located at the lower right corner of the machine.

Technical Specification

| Sr. No. | Specification | Details |

|---|---|---|

| 1 | Model No | VJTDP-Pilot Scale |

| 2 | Certificates | GMP, ISO, CE |

| 3 | Production Capacity | 1 inch X 1 inch – 15,000 units per day. |

| 4 | Size of Film drawn | 120 mm width X 100 meter roll. |

| 5 | Accepted web widths | The machine is made to be equipped with any web width ≤ 150 mm. |

| 6 | Coating width | The maximum coating width is 120 mm |

| 7 | Max. coating speeds | Mechanical web speed is infinitely variable 0.1m/s to 0.9 m/s. During the coating process, the speed needs to be slower to dry the wet film. |

| 8 | Temperature Range | Room ambient temperature up to 90 degrees Celsius. |

| 9 | MOC of Contact Part | All Product touching part is SS 316 |

| 10 | MOC of Non-contact part | Aluminium and SS304 |

| 11 | Power Supply | 230 Volts, 50Hz, 16 Amp Secured / 110 Volt, 50 Hz, 32 Amp |

| 12 | Electric Consumption | 1.0 Kw per hour. |

| 13 | Coating system | The coating System is built up of a precise coating knife for coating width up to the maximum 150 mm and can easily be reduced by Teflon strips to any width. The usable coating width is 120 mm for the maximum coating width of 150 mm with the below mention accuracy. The coating knife is fed solution by a precision tooth gear pump or peristaltic pump. |

| 14 | Coating accuracy | +/- 1 to 5 μm for a 100 μm dry coating over the entire coating width |

| 15 | Winders | All winders (unwinder for carrier foil, unwinder for backing foil, and rewinder for laminates) are with shafts for 3”. |

| 16 | Interface | HMI Delta. |

| 17 | Web coater Dimension (LXWXH) in mm | 1435 mm (L) X 645 mm (W) X 700 mm (H) |

| 18 | Weight | 250 kg. (Approximate) 350 Kg with packing. |

| 19 | Solution stand (LXWXH) mm | 380mm(L) X 380mm (W) X 1175 mm (H) Weight – 20 kg (Approximate) With packing 120 (Approximate) |

Safety Features

- Emergency stop switch

- Auto stop feature when process time completes

Certifications

01.

CE Certificate

02.

GMP Certificate

03.

ISO Certificate

04.

MSME Certificate

Frequently Asked Questions

We understand that you may have questions about our TDP & ODF Machine Pilot Scale, its applications, and how it can benefit your specific needs. Here are some common questions and answers to provide you with quick and helpful information:

The VJ Instruments Film Former Coating Machine is designed for the development and small-scale production of Transdermal Therapeutic Delivery System (TDS) laminates and Edible Films/Oral Dissolvable Films (EDF/ODF) without any further modification.

This machine features an ultra-precise coating knife that guarantees exceptional product quality with an accuracy of ±1% across the entire coating width. It also allows for continuous coating and successive lamination.

Yes, you can. The temperature settings are adjustable, allowing you to control the heated air in the dryer, ranging from room ambient temperature up to 90°C.

All product-touching parts are made of stainless steel or aluminum, ensuring product quality and hygiene.

The maximum coating width is 120 mm, and the mechanical web speed is infinitely variable from 0.01 m/min to 3 m/min. During the coating process, the speed may need to be slower to ensure proper drying of the wet film.

The drying process can be observed through a window inserted in the dryer lid, allowing you to monitor the process in real-time.

Yes, we provide comprehensive customer support and assistance to help you make the most of your VJ Instruments Film Former Coating Machine. Contact our team for any inquiries or support needs.

The model number for this machine is VJTDP-Pilot Scale.

International Clients

Industrial Clients

IITs, AIIMS, CSIR, Government and Private Institutes

Related Products

Tabletop Transdermal Patch Machine

VJ Instruments’ Cutting-Edge Tabletop Transdermal Patch Machine: Revolutionizing TDP and ODF Production The VJ Instruments