VJ Instruments'

Lab-Mini Spheronizer: Solutions for Pharmaceutical Spheronization

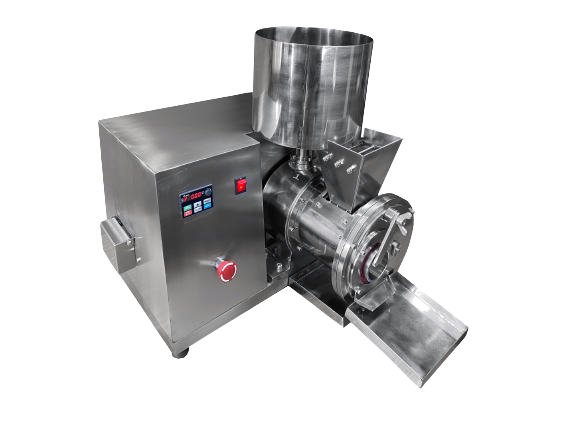

Spheronizer - The Ultimate Spheroid Manufacturing Solution

Application

The function of a spheronizer is to convert extrudes into spheroids. Spheronization is the necessary second step of granulation by extrusion – spheronization process where pharmaceutical products are made into small spheres or spheroids.

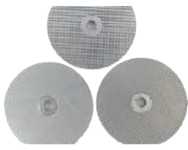

Spheronizer consists of a plate, which is having a special cross-hatched groves, known as chequered plate. This plate rotates inside a cylindrical bowl.

The radial clearance between the plate and the bowl is kept minimal (<0.3 mm) to reduce the powder leakage.

Purging air is supplied in this gap to prevent the falling of powder beneath the chequered plate. This air also helps for the evaporation of excess moisture from extrude and prevent particle agglomeration.

While rotating in the grooved plate with pre-desired groove size, the vermicelli will fragment into pieces with length equal to the diameter of extrudes.

Broken extrudes, because of the tangential force and centrifugal force, collide with the cylindrical wall of the spheronizer. The rotating rope type movement of extrudes at the outer border of the bowl gives a rolling action on the fragmented extrudes and it will be converted to spheres.

When the particles attain required spherical shape they are centrifugally discharged through the discharge door which opens into the discharge hopper.

Technical Specification

| Sr. No. | Specification | Details |

|---|---|---|

| 1 | Model No | VJSP-01 |

| 2 | Certificates | GMP, ISO, CE |

| 3 | Chequered Plater | 3.00 mm Pitch Optional with extra cost.

|

| 4 | Production Capacity | 40 to 500 gm per batch (2-6 kg/hr depends on formulation.) |

| 5 | Product | Any Aqua base or solvent base formulation. |

| 6 | RPM | 100 to 1400 rpm |

| 7 | Electric Accessories | 230 V 1 Phase 50 Hz |

| 8 | Air purged inlet (Optional) | Filter Air with min 2 Bar Pressure supply should be provided by the Client. |

| 9 | MOC Contact Parts | SS 316 |

| 10 | MOC Non-Contact Parts | SS 304 |

| 11 | Hardware | Standard Make (Bearing shaft seal of SKF etc or equivalent) |

| 12 | Finish | Non Contact Area Matt Finish Contact area Matt Finish Machine part- Machine Finish |

| 13 | Drive Motor | Crompton or equivalent |

| 14 | Switch Gear | Standard Make |

| 15 | VFD | Delta |

| 16 | Documents | User |

Note: Capacities mentioned above depend on samples used and may vary accordingly. VJ Instruments product development is a continuous process so specifications may change without prior notification.

Safety Features

- Emergency stop switch

- Auto stop feature when process time completes

Certifications

01.

CE Certificate

02.

GMP Certificate

03.

ISO Certificate

04.

MSME Certificate

Frequently Asked Questions

We understand that you may have questions about our Lab-Mini Spheronizer, its applications, and how it can benefit your specific needs. Here are some common questions and answers to provide you with quick and helpful information:

A Spheronizer’s main function is to convert extrudes into small, uniform spheres or spheroids, commonly used in pharmaceutical and granulation processes.

The Spheronizer achieves this by using a grooved plate that rotates within a cylindrical bowl. As extrudes break into pieces and collide with the bowl’s walls, they undergo a rolling action that transforms them into spheres.

The Lab-Mini Spheronizer has a capacity of 100 to 500 gm per batch (approximately 15 kg per hour). It features stainless steel construction, modular design, CNC-processed components, and variable speed control for the Checkered Plate.

Yes, safety features include an emergency stop switch and an auto-stop function when the process time completes, ensuring safe and efficient operation.

International Clients

Industrial Clients

IITs, AIIMS, CSIR, Government and Private Institutes

Related Products

Lab-Scale Screw Extruder & Spheronizer Combo

VJ Instruments’ Lab-Scale Extruder & Spheronizer Combo Lab-Scale Extruder and Spheronizer Combo is a seamlessly

Lab-Mini Screw Extruder

VJ Instruments’ Lab-Mini Screw Extruder: Tailored Solutions for Pharmaceutical Pelletization Screw Extruders are versatile and

Hot Melt Extruder

VJ Instruments’ Hot Melt Extruder: Revolutionizing Pharmaceutical Formulations Welcome to VJ Instruments, your trusted source

Die Roller Extruder

VJ Instruments’ Die Roller Extruder: Precision Extrusion Made Easy The Die Roller Extruder is a